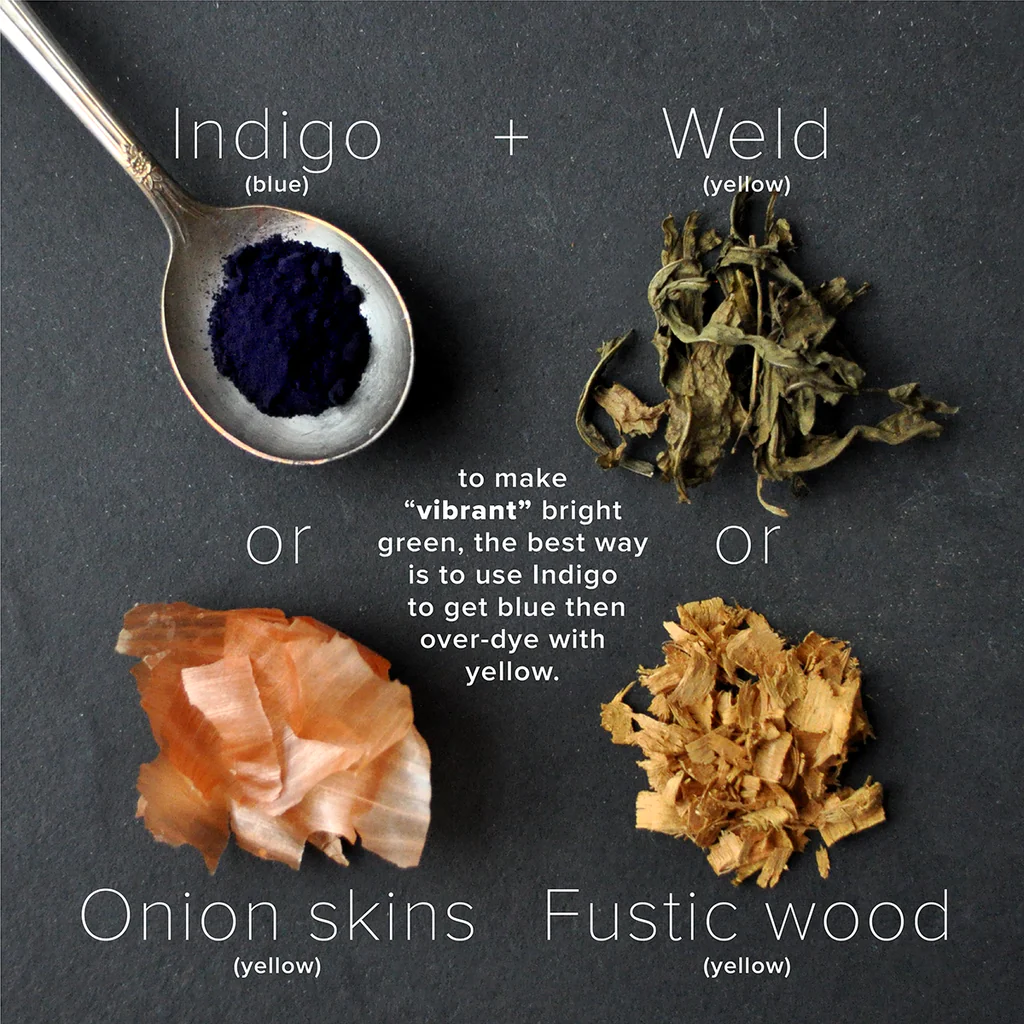

Textile dyeing evidences have found to the Neolithic period. It has a history of older than 12000 years. The Indigo dye is the oldest and most widely used. The dyes derived from plants, invertebrates and minerals are called natural dyes. The natural dyes majorly obtained from plants which are known as vegetable dyes – flowers, roots, dried fruit extracts, dried bark etc.

For vegetable origin of natural dyes, the best source of natural dyes are the different parts of plants and trees. Most natural dyes are extracted from different parts of plants and trees. Natural dyes and pigments are taken from the following parts of plants/trees:

- Seed

- Root

- Stem

- Barks

- Leaves

- Flowers

Information about vegetable dyes – plant derived dyes

- Teak Leaf – Crimson to maroon

- Marigold – Sap green

- Eucalyptus – Leaf Green

- Catechu – Brown

- Gamboge – Dark mustard yellow

- Chestnut – Peach, yellow

- Indigo – Blue

- Madder – Red, Pink, Orange

- Pomegranate – Yellow ochre

- Turmeric – Yellow

- Onion Pill – Light pink

The origin of the colors red, brown, and oranges are first attested in textile sites ranging from neolithic period to Bronze Age over across the Egypt, Mesopotamia and Europe. Later the blue, yellow and green started appearing.

Natural dyes are dyeable only on natural source fabric, e.g. cotton, linen, wool and silk. The color fastness is poor in general practice but if it process with proper dying method by following all correct parameters the fastness is achieved. The loom story practice natural dyes for dying and printing process with natural dyes. We have achieved good washing fastness for natural dyes after several researches. Natural dyes are hard to match with previous shades because of many reasons.

- pH level of water/dye bath

- Temperature

- Fiber structure

Method of dyeing – Natural dyes

Preparation of fabric is the most important process of any kind of dying method. The fabric is pre-treated for better absorbency. The fabric carries impurities in raw material and also while weaving which looks off white and rough. Such unbleached fabric is call greige fabric. To make it white it is dipped or treated with cow dung followed by washing. Now a days the conventional method is not carried out so usually greige fabric is scoured using ( sodium hydroxide) chemicals to make it white or to desize it for dying, this process is called scouring. Then the fabric become ready to dye in harda. It is soaked in harda solution and dried. The dried fabric now looks yellowishcin color, then it is kept to for curing process. The harda acts as a mordant for next procedure of dying. with harda treatment fabric doesn’t get the fastness also it helps to get proper desirable shade. Then the fabric is boiled with subsequent solution of particular shade or alum.

The procedure is quite lengthy but it is neither harmful chemicals nor carcinogenic components which or common in synthetic dyes. It is safe to nature or human being. It is sustainable and is being so popular to European countries.

Here are few clothing in natural dyes on the loom story website

-

Product on sale

Khadi kalamkari kurtaOriginal price was: ₹2,399.₹1,199Current price is: ₹1,199.

Khadi kalamkari kurtaOriginal price was: ₹2,399.₹1,199Current price is: ₹1,199. -

Product on sale

Khadi kalamkari blue skirtOriginal price was: ₹2,299.₹1,149Current price is: ₹1,149.

Khadi kalamkari blue skirtOriginal price was: ₹2,299.₹1,149Current price is: ₹1,149. -

Product on sale

Khadi kalamkari dressOriginal price was: ₹2,499.₹1,249Current price is: ₹1,249.

Khadi kalamkari dressOriginal price was: ₹2,499.₹1,249Current price is: ₹1,249. -

Product on sale

Khadi Kalamkari handprinted jacketOriginal price was: ₹3,299.₹1,649Current price is: ₹1,649.

Khadi Kalamkari handprinted jacketOriginal price was: ₹3,299.₹1,649Current price is: ₹1,649. -

Product on sale

Khadi kalamkari jacketOriginal price was: ₹3,299.₹1,649Current price is: ₹1,649.

Khadi kalamkari jacketOriginal price was: ₹3,299.₹1,649Current price is: ₹1,649. -

Product on sale

Khadi kalamkari topOriginal price was: ₹1,199.₹599Current price is: ₹599.

Khadi kalamkari topOriginal price was: ₹1,199.₹599Current price is: ₹599. -

Product on sale

Khadi kalamkari printed tunicOriginal price was: ₹1,699.₹849Current price is: ₹849.

Khadi kalamkari printed tunicOriginal price was: ₹1,699.₹849Current price is: ₹849. -

Product on sale

Khadi kalamkari tunicOriginal price was: ₹1,399.₹699Current price is: ₹699.

Khadi kalamkari tunicOriginal price was: ₹1,399.₹699Current price is: ₹699. -

Product on sale

Kalamkari ikat reversible jacketOriginal price was: ₹3,400.₹1,999Current price is: ₹1,999.

Kalamkari ikat reversible jacketOriginal price was: ₹3,400.₹1,999Current price is: ₹1,999.

Today in business environment, sustainability is an important to think and switch towards. Many brand are switching to sustainable fashion. many designers are thinking to launch the sustainable label. Natural dyes are the one option for the most pollutant releasing industry that is Fashion and textile industry rising for fast fashion demand.